Engineering Pro Guides is your guide to passing the Mechanical & Electrical PE and FE Exams

Engineering Pro Guides provides mechanical and electrical PE and FE exam technical study guides, practice exams and much more. Contact Justin for more information.

Email: contact@engproguides.com

EXAM TOOLS

Key Concepts & Skills

for the Machine Design & Materials P.E. Exam

Introduction

One of the most important steps in an engineer's career is obtaining the professional engineering (P.E.) license. It allows an individual to legally practice engineering in the state of licensure. This credential can also help to obtain higher compensation and develop a credible reputation. In order to obtain a P.E. license, the engineer must first meet the qualifications as required by the state of licensure, including minimum experience, references and the passing of the National Council of Examiners for Engineering and Surveying (NCEES) exam. Engineering Pro Guides focuses on helping engineers pass the NCEES exam through the use of free content on the website, www.engproguides.com and through the creation of books like sample exams and guides that outline and teach you how to pass the PE exam.

The key to passing the PE exam is to learn the key concepts and skills that are tested on the exam. There are several issues that make this key very difficult. First, the key concepts and skills are unknown to most engineers studying for the exam. Second, the key concepts and skills are not contained in a single document. The technical guide teaches you the key concepts and skills required to pass the Machine Design & Materials Mechanical P.E. Exam.

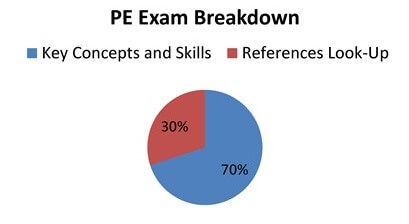

The full exam tests the key concepts and skills which will count for approximately 70% of the PE exam. The remaining 30% of the PE exam will be based on looking up solutions in your references. If you have sufficient experience in the field, then you will know the answers to these types of problems. If you don't have the experience, then you will need to be knowledgeable in the various Machine Design & Material References. You can test your knowledge through the references exam.

What is on the Machine Design & Materials PE Exam?

In order to determine what is on the PE exam, I have gone through the NCEES outline topics, shown below, and researched each topic and subtopic. Next, I ensured that the material met the following 4 criteria:

- (1) Must be commonly encountered in the Machine Design & Materials field

- (2) Must be testable in roughly 6 minutes per problem

- (3) Must be used by practicing engineers and

- (4) Must test the principle or application.

Through this technique I have come up with the key concepts and skills that are on the Machine Design & Materials PE exam. These key concepts and skills are taught in the technical study guide and are tested on the full exam. The references exam covers any other material that is missed in the technical study guide and full exam. The references exam focuses on problems that require you to use your references to find solutions, which is a skill needed in actual practice.

The Machine Design & Materials Mechanical PE exam will focus on the following topics as indicated by NCEES. https://ncees.org/engineering/pe/

NCEES Outline

- I. Principles (40 questions)

-

A) Basic Engineering Practice (9 questions)

- 1 Engineering terms and symbols

- 2 Interpretation of technical drawings

- 3 Quality assurance/quality control (QA/QC)

- 4 Project management and economic analysis

- 5 Units and conversions

- 6 Design methodology (e.g., identifying requirements, risk assessment, verification/validation)

-

B) Engineering Science and Mechanics (10 questions)

- 1 Statics

- 2 Kinematics

- 3 Dynamics

-

C) Material Properties (8 questions)

- 1 Physical (e.g., density, melting point, optical)

- 2 Chemical (e.g., corrosion, alloys, oxidation)

- 3 Mechanical

- i) Time-independent behavior (e.g., modulus, hardness, thermal expansion)

- ii) Time-dependent behavior (e.g., creep, viscoelastic, thermal conductivity)

-

D) Strength of Materials (10 questions)

- 1 Stress/strain (e.g., tension, compression)

- 2 Shear

- 3 Bending

- 4 Buckling

- 5 Torsion

- 6 Fatigue

- 7 Failure theories (e.g., Von Mises, maximum shear stress)

- E) Vibration (3 questions)

- 1 Natural frequencies (e.g., linear, bending torsional) and acoustics

- 2 Damping (e.g., frequency, damping ratio, critical damping)

- 3 Forced vibrations (e.g., magnification factor, transmissibility, balancing, isolation)

-

A) Basic Engineering Practice (9 questions)

-

A. Mechanical Components (18 questions)

- 1. Pressure vessels and piping (e.g., thick/thin wall)

- 2. Bearings (e.g., types, lubrication analysis, life-load analysis)

- 3. Gears (e.g., types, speed analysis, force analysis)

- 4. Springs (e.g., types, force analysis, fatigue analysis)

- 5. Dampers (e.g., types, selection)

- 6. Belt, pulley and chain drives (e.g., types, force analysis)

- 7. Clutches and brakes (e.g., types, torque/force analysis)

- 8. Power screws (e.g., types, lifting and lowering torque, locking conditions)

- 9. Shafts and keys (e.g., torsion, bending, static/fatigue failure, stress risers)

- 10. Mechanisms (e.g., linkages, cams, slider crank, levers, force analysis, kinetic analysis)

- 11. Basic mechatronics (e.g., electromechanical interfaces, sensors, basic circuits, basic controls)

- 12. Hydraulic and pneumatic components (e.g., pumps, cylinders, presses)

- 13. Motors and engines (e.g., energy conservation, efficiency)

-

B. Joints and Fasteners (12 questions)

- 1. Welding and brazing (e.g., types, symbols, stress analysis)

- 2. Bolts, screws, rivets (e.g., grade/class selection, preload, fastener group force analysis)

- 3. Adhesives (e.g., types, analysis)

-

C. Supportive Knowledge (10 questions)

- 1. Manufacturing processes (e.g., machining, molding, heat treatment)

- 2. Fits and tolerances

- 3. Codes and standards

- 4. Computational methods and their limitations (e.g., FEA, CAE)

- 5. Testing and instrumentation sample of the symbols used in Machine Design.

How to Determine What Will be on the PE Exam?

Find Resources on the NCEES Outline Topics

The Machine References page has all the necessary resources you need for each individual topic and subtopic. You should use this page to gather all the necessary resources. Once you have the resources, then you need to narrow down the information that deals specifically with the PE exam.

Focus on Material that Meets the Following Four Criteria

The amount of resources and topics on the NCEES outline are daunting. You need a way to focus your studying on the material that will be on the PE exam. The best way to focus your studying is to use the following four criteria. If certain material within the resources does not meet the four criteria then you can glance over the information. If the information does meet the four criteria then you should make sure you understand the information well and if necessary you should tab the information or write down the formulas/equations for quick and easy use.

Criteria 1: Must be Commonly Encountered

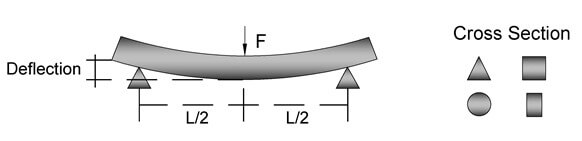

(1) First, the concept and skill must be commonly encountered in the Machine Design & Materials field of study. For example, in the Machine Design & Materials field: Calculating stresses due to bending within a beam is a task that is regularly conducted (as shown in the figure above), but the task of calculating the stress due to torsion in beams is not commonly encountered. Another example would be loading a ductile material like copper or aluminium in torsion. A brittle material like steel would be loaded in torsion. The questions on the PE exam should reflect commonly encountered situations and not atypical situations that are solely meant to cause confusion.

Criteria 2: Must be Tested in 6 Minutes per Problem

(2) Second, the skill and concept must be testable in roughly 6 minutes per problem. There are (40) questions on the morning exam and you will be provided with 4 hours to complete the exam. The same is true for the afternoon portion of the exam. This results in an average of 6 minutes per problem. This criterion limits the complexity of the exam problems and the resulting solutions. For example, calculating the second moment of area in a 3-sided fillet weld is common in the Machine Design & Materials field, but the calculation is very lengthy because of the number of steps involved and is typically done on excel. Thus, you can eliminate these types of lengthy calculations and you can expect that questions that involve lengthy calculations will either give certain steps as given assumptions or will just test your overall understanding of how the calculation is carried out on excel.

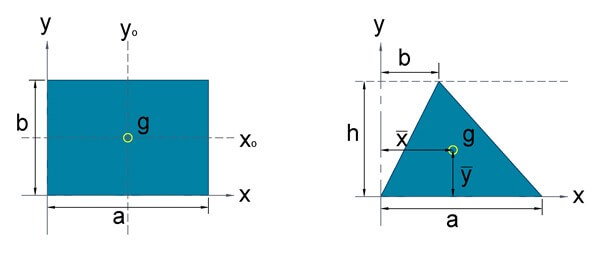

For example, they could ask that in a 3-sided fillet weld, if a certain length is adjusted, then how will it effect the result? The 6-minutes criterion and the low-tech calculator also eliminates any complex mathematics. Just like in the picture above, the moment of inertia calculations should be limited to easier geometries. If the solution is too complex, then you are probably missing a simple way to solve the problem.

Criteria 3: Must be Used by Practicing Engineers

(3) Third, the key concepts and skills must be used or be known by practicing Mechanical engineers in the Machine Design & Materials field. This criterion is similar to the first criterion. However, this criterion filters the concepts and skills further by limiting the field to material encountered and used by practicing engineers.

The Machine Design & Materials fields are vast and there are many different avenues an engineer can take. Two diverging paths are those engineers involved in research and those who practice. Research engineers are pushing the boundaries of the field and are highly focused in their specific area of the field. The Professional Engineering exam does not cover emerging technologies or highly focused material. The exam focuses on material that practicing engineers may use in their day to day careers.

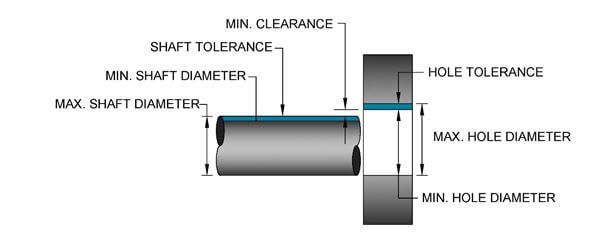

The exam is more focused on practicing topics like standard fits and tolerances (picture above) and standard bolt, screw and washer sizes.

Criteria 4: Must Test the Principle or Application

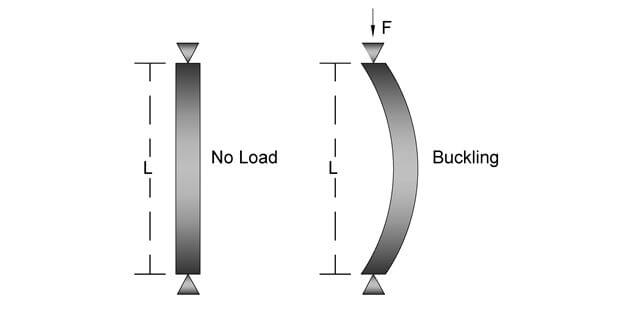

(4) The P.E. Exam must test the principle or application of the skill and concept and not the background knowledge of the topic or concept. The exam also does not cover background information on the NCEES topics. The P.E. Exam is meant to prove that the test taker is minimally competent to practice in the Mechanical Engineering – Machine Design field. The exam is less concerned with theory and more with the principle or application of the theory, skill or concept. For example, the P.E. exam is less concerned with the derivation of the column buckling formulas and more concerned with your ability to use those formulas to determine buckling and stress.

Use the Criteria to Determine What is on the PE Exam.

In summary, Engineering Pro Guides products are intended to teach the necessary skills and concepts to develop a minimally competent, practicing professional engineer in the Mechanical Engineering – Machine Design & Materials field, capable of passing the P.E. exam. Even if you decide not to use Engineering Pro Guides in your studying, you should be aware of these four criteria when studying. These criteria will help to ensure that you are truly focusing on the material that will be on the PE exam. Studying for the PE exam can be very difficult and time consuming without these four criteria. NCEES provides little information on what you should study besides the outline, so you need these four criteria to focus your studying.